Lỗi định dạng email

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Applications and latest market conditions of PA12

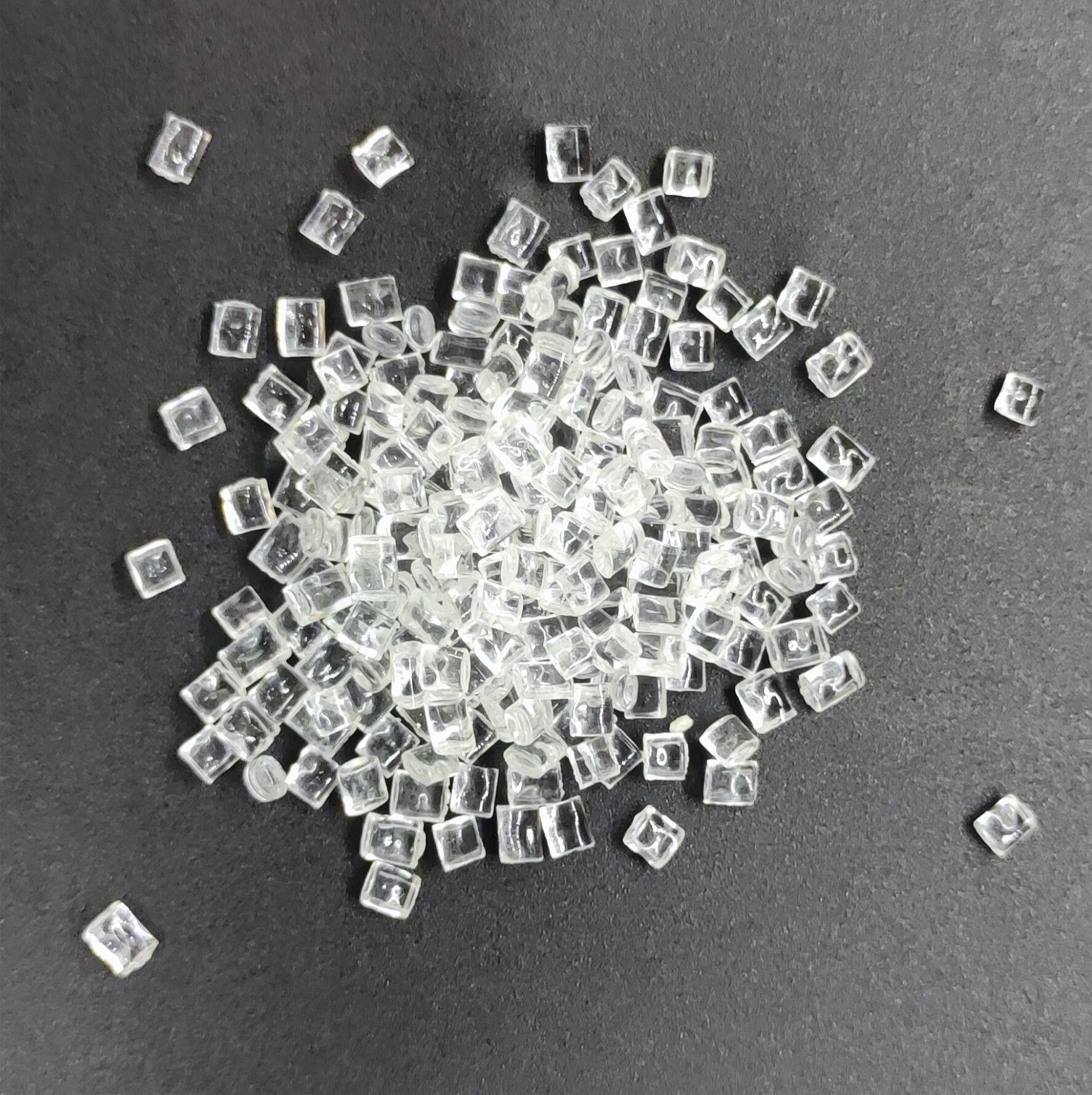

Overview of PA12

PA12 is nylon 12, also known as polylaurolactam and polylaurolactam. It is a high-performance long carbon chain nylon.

The relative density of nylon 12 is only 1.01-1.03. Benefiting from the increased lightweight requirements, automobiles are the largest demand market for nylon 12, and it is still growing. In addition, the rapid development of the 3D printing industry has expanded the demand for high-performance printing materials, and nylon 12 materials perform well in 3D printing. Against this background, the global nylon 12 market continues to expand. With the rapid development of my country's electronics, automobiles, machinery, electric vehicles, energy storage and other industries, China has become one of the world's largest consumer markets for nylon 12.

It is particularly worth mentioning that in addition to new energy vehicles, with the advancement of energy storage thermal management technology, liquid-cooled energy storage has become an industry trend for industrial and commercial energy storage and container energy storage. Among them, PA12 has become a liquid-cooled tube due to its excellent performance. The preferred material for roads.

1.Structural properties

There are non-polar methylene groups in nylon 12, and the number is large, which makes the nylon 12 molecular chain more flexible; the amide group in nylon 12 is polar and has a large cohesive energy , hydrogen bonds can be formed between its molecules, making the arrangement of molecules more regular. Therefore, nylon 12 has high crystallinity and high strength. Nylon 12 (PA12) has low water absorption, good low temperature resistance, good air tightness, excellent alkali and grease resistance, medium resistance to alcohols, inorganic dilute acids and aromatic hydrocarbons, good mechanical and electrical properties, and is a natural Fire-extinguishing materials.

1)Density

The relative density of nylon 12 is only 1.01-1.03, which is the smallest among all engineering plastics. This plays a certain role in reducing the weight of cars and reducing fuel consumption. When compared by volume, nylon 12 has advantages in price and performance.

2)Melting point

The melting point of nylon 12 is 172-178°C, which is slightly lower than nylon 11. It can fully meet the working environment temperature requirements of automobile fuel pipes and air brake pipes.

3)Water absorbency

As we all know, the biggest disadvantage of nylon products is that they have high water absorption and it is difficult to ensure dimensional stability. However, due to the increase in methylene molecules in nylon 12, the influence of hydrophilic groups is greatly reduced. Therefore, nylon 12 has the lowest water absorption rate among nylon products, which reduces the performance and size of the product due to water absorption. changes, which gives nylon 12 a great advantage. After absorbing water, the tensile strength of nylon 12 decreases very little, while nylon 66 and nylon 6 change greatly.

4)Imapact strength

Impact strength is an important technical specification, especially for nylon 12 tubing that is frequently exposed to air. Nylon 12 was tested according to standards at -20°C and -40°C. There was no breakage and it fully complied with the usage requirements. Nylon 12 has excellent impact resistance.

5)Low temperature performance

Nylon 12 has the lowest brittleness temperature of -70 degrees Celsius, so it can be widely used in low-temperature-resistant parts.

6)Flexibility

The impact of plasticizers on the physical properties of nylon 12 is concentrated on the elastic modulus of the resin. There are three basic types of nylon 12 resins, the main difference between which is the flexibility due to the plasticizer content. As the content of extractable components of the plasticizer increases, the elastic modulus of the resin decreases.

7)Low wear and low friction properties

Nylon 12 has excellent low wear, low friction and self-lubricating properties, so nylon 12 products have very low friction noise.

8)Fuel resistance

In automobiles, the current use of oxygenated fuels, highly aromatic fuels, and alcohol blends can cause the breakdown of many hose materials. After testing, only nylon 11, nylon 12 and fluorocarbon resin elastomers can be used in this environment. Under the action of automobile fuel, all nylons will swell, resulting in dimensional changes, especially in gasoline containing methanol. Nylons containing a large number of amide groups, such as nylon 6, are soluble more than nylons containing a small amount of amide groups, such as nylon 12%. The increase is much larger. Research has found that fuel containing 15% methanol has a great impact on nylon

9)Resistant to zinc chloride solution

Zinc chloride can be found in the undercar environment. Under certain temperatures and humidity, road salt reacts with galvanized steel or zinc-containing primer to form small amounts of zinc chloride. Zinc chloride is highly corrosive, but nylon 12 is highly resistant to zinc chloride solutions. Ozone aging, ultraviolet radiation, temperature conditions, etc. will cause varying degrees of damage to parts and reduce their service life. Since there are no + 2 3 2 + unsaturated double bonds in nylon 12 that are susceptible to ozone attack, ozone aging does not occur.

In addition, nylon 12 has high crystallinity, high melting temperature, and good heat resistance and stability. After adding a heat stabilizer, the heat resistance is doubled. When sunlight shines on it, its energy can cause the chemical bonds of organic matter to break. The bond energy of C-H, C-O, and C-N bonds in nylon 12 is very large, and ultraviolet rays are not enough to destroy them. It can only destroy the C-C bond with smaller bond energy. Therefore, after adding appropriate anti-aging agents to the raw materials, nylon 12 The UV resistance is very good.

Application of PA12

Nylon 12 is the most widely used long carbon chain nylon. In addition to having most of the general properties of general nylon, it has low water absorption, high dimensional stability, high temperature resistance, corrosion resistance, good toughness, and easy processing. advantage. Compared with PA11, another long carbon chain nylon material, the price of PA12's raw material butadiene is only one-third of PA11's raw material castor oil. It can replace PA11 and be used in most scenarios, such as automobile manufacturing, oil and gas transportation, electronics and electrical , 3D printing and many other fields have a wide range of applications. With the rapid development of my country's electronics, automobile, machinery and other industries, China has become the world's third largest consumer market for nylon 12.

1) Car parts

Nylon 12 can be widely used in automotive fluid delivery lines, including fuel lines, clutch lines, vacuum brake booster lines, air brake lines, battery coolant lines and joints of the above pipelines. Because of its safety and reliability, it is an excellent automotive Lightweight materials.

2) Duct cables

PA12 material has been used in onshore and offshore flexible risers, gas pipes, linings, and steel pipe coatings for many years. It can prevent seawater erosion and corrosion of oil fluids, and is used to manufacture flexible pipes for transporting subsea oil and gas products and merged fluids. Riser pipes, natural gas distribution systems at pressures up to 20bar, etc. Nylon 12 has a low embrittlement temperature and excellent weather resistance, and is especially suitable for the manufacture of field special purpose communication cables that require use in all climates (-50~70℃).

3) 3D printing

Compared with other materials, PA12 powder has excellent characteristics such as high fluidity, low static electricity, low water absorption, moderate melting point and high dimensional accuracy of products. Its fatigue resistance and toughness can also meet the needs of workpieces that require higher mechanical properties, so nylon 12 Gradually becoming an ideal material for 3D printing of engineering plastics.

4) Medical

PA12 is also used as a nursing medical material. The mechanical properties of the catheter material are particularly important. The catheter must be easy to thread, but must not bend and never break. PA12 is an excellent material for catheter production due to its high burst pressure, good flexibility, chemical resistance, compatibility with body fluids and non-toxicity. It complies with the medical product requirements of the US Food and Drug Administration and the European Union.

5) Daily necessities

PA12 has excellent fatigue resistance, no need for spraying, and can be used for glasses frames.

6) Advanced coatings and adhesives

Coating metal with nylon 12 has the best abrasion resistance of the coating, so it is often used to produce advanced coatings and adhesives. PA12 can be used in the dish racks of new dishwashers to ensure that the metal dish racks are not worn in high-temperature detergent environments and have a longer service life; it can also be used in outdoor furniture, such as park benches, when coated with PA12 It can effectively prevent metal corrosion.

7) Film sheet

PA12 film is transparent, non-toxic, has low water vapor and gas (O2, N2, CO2) transmittance, and its performance remains unchanged after being stored in boiling water for one year. It can be used with polyethylene blow molding and extrusion composite film to produce film sheets. It protects and packages food and has the advantages of flavor preservation, steam sterilization resistance and low temperature resistance. Nylon 12 has good adhesion to metal. When bonding food, the sealing value reaches 100% and the peel strength is high.